Hantechn@ High Hardness Laser e Welded Sintered Diamond E Bona Mahlaku a Sehang a Metsi

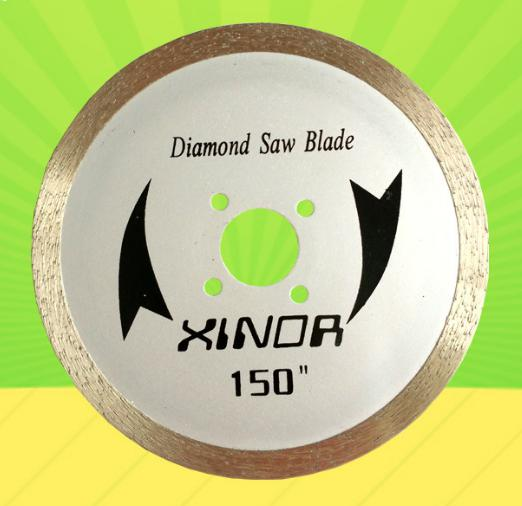

Qala leeto la ho nepahala le boqapi ka Hantechn@ High Hardness Laser-Welded Sintered Diamond Wet Cutting Blades. E etselitsoe ho hlalosa bocha boiphihlelo ba hau ba ho itšeha, li-blade tsena li bonts'a theknoloji e tsoetseng pele. Mohaho o entsoeng ka laser-welded o tiisa matla le botsitso bo ke keng ba lekanngoa, ho fana ka maqeba a nepahetseng a metsi habonolo.

Hore na o rakonteraka ea hloahloa kapa motho ea chesehelang DIY ea chesehang, mahare ana a sehang a metsi a ts'episa ho nepahala, ho etsa hore e 'ngoe le e 'ngoe e be mosebetsi o tsoileng matsoho bakeng sa merero ea hau.

| Mahlaseli a Taemane a Metsi a Seha | |||

| Diameter | Sekoti | botegeniki | Maikaelelo |

| 100mm 115 limilimithara | 20mm, 22.23mm, 32mm, 50mm | Khatello e batang Tobetsa e Chesang Ho chesoa ka laser | Formarble, granite, ceramic, konkreite |

| 125 limilimithara 150 limilimithara | 20mm, 22.23mm, 32mm, 50mm | Khatello e batang Tobetsa e Chesang Ho chesoa ka laser | Formarble, granite, ceramic, konkreite |

| 180 limilimithara 230 limilimithara | 20mm, 22.23mm, 32mm, 50mm | Khatello e batang Tobetsa e Chesang Ho chesoa ka laser | Formarble, granite, ceramic, konkreite |

| 250 limilimithara 300mm | 20mm, 22.23mm, 32mm, 50mm | Khatello e batang Tobetsa e Chesang Ho chesoa ka laser | Formarble, granite, ceramic, konkreite |

| 350 limilimithara 400mm | 20mm, 22.23mm, 32mm, 50mm | Khatello e batang Tobetsa e Chesang Ho chesoa ka laser | Formarble, granite, ceramic, konkreite |

| 450 limilimithara 500 limilimithara Oboholo bo sebetsang | 20mm, 22.23mm, 32mm, 50mm | Khatello e batang Tobetsa e Chesang Ho chesoa ka laser | Formarble, granite, ceramic, konkreite |

Ikutloe u le sehlohlolong sa ho itšeha ka bokhabane ka li-laser-welded sintered diamond saw blades tse sehang tse metsi. E entsoe ka ho nepahala le ho tšoarella kelellong, li-blades tsena li hlalosa bocha litekanyetso tsa ho itšeha ka metsi. Ke sena se ba khethollang:

Boqapi ba Taemane bo thata bo phahameng

Li-blade tsa rona tse kolobileng li entsoe ka bokhabane ka litaemane tse thata haholo, tse netefatsang ts'ebetso e ikhethang e emelang nako e telele. Ho thatafala ha litaemane ho tiisa bophelo bo bolelele le ho nepahala, ho etsa hore mahare ana e be khetho ea pele bakeng sa mesebetsi e thata ea ho itšeha.

Theknoloji ea Laser-Welded

Kaho e ncha ea laser-welded ea li-blades tsena e phahamisa matla le botsitso ba tsona ho ea holimo. Theknoloji ena e tsoetseng pele e tiisa maqhama a se nang moeli pakeng tsa likarolo tsa daemane le lehare, e fana ka botšepehi bo ke keng ba lekanngoa nakong ea mesebetsi ea ho itšeha ka metsi. Ha ho na ho sekisetsa, ke ts'ebetso e phahameng feela.

Likarolo tsa Sintered Diamond

Ho matlafatsa ts'ebetso ea lehare le ho sebetsa hantle, likarolo tsa daemane tse sirelelitsoeng ke karolo ea mantlha ea mahare a rona a sehang a metsi. Ts'ebetso ea sintering e tiisa maqhama a tiileng pakeng tsa litaemane le matrix, e leng se etsang hore mahare a be matla ha a tobane le likopo tse hlokang ho itšeha ka metsi.

Bokhabane ba ho Kota Metsi

E etselitsoe feela lits'ebetso tsa ho itšeha ka metsi, li-blades tsa rona li fana ka ts'ebetso le ho itšeha ho pholileng ho feta leha e le neng pele. Mokhoa oa ho itšeha ka metsi o fokotsa ho hlahisa mocheso le ho fokotsa lerōle, ho theha sebaka se hloekileng le se phutholohileng sa ho sebetsa. Lahla mocheso o feteletseng le mathata a amanang le lerole.

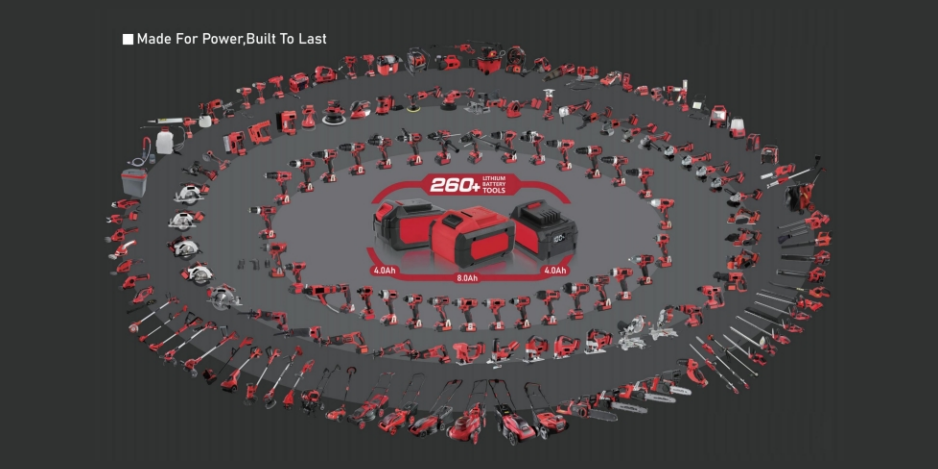

Tšebeliso e fapaneng

Li-blade tsena tse kolobileng li entsoe bakeng sa ho ikamahanya le maemo, li etsa hore e be tse loketseng mesebetsi e fapaneng ea ho itšeha ka metsi ho pholletsa le thepa le merero e fapaneng. Hore na o sebetsa ka lithaele, majoe, kapa konkreite, li-blade tsa rona li ikamahanya le mosebetsi o teng, li fana ka liphetho tse tsitsitseng le tsa botsebi.

Ho Thata ho Phahameng bakeng sa Maemo a Phephetso

Boima bo phahameng ba tlhaho ba li-blades tsa rona bo tiisa ho tiea le ho nepahala, esita le maemong a thata ka ho fetisisa a ho itšeha a metsi. Sebetsana le merero e hlokang boitlamo ka boitšepo, u tseba hore li-blades tsa rona li sebetsa, li fana ka litholoana tse ikhethang nako le nako.

Liphetho tsa Kereiti ea Setsebi

Hore na o rakonteraka ea nang le boiphihlelo kapa moratuoa ea inehetseng oa DIY, daemane ea rona e entsoeng ka laser-welded sintered blades e sehang e fana ka tiiso ea sephetho sa maemo a holimo. Ntlafatsa boiphihlelo ba hau ba ho itšeha ka li-blade tse kenyelletsang ho nepahala, ho tšoarella le ho sebetsa hantle.

Tlosa bokhoni bo felletseng ba mesebetsi ea hau ea ho itšeha ka metsi ka li-blade tsa rona tse tsoetseng pele-moo boima bo phahameng bo kopanang le theknoloji e tsoetseng pele bakeng sa ts'ebetso e ke keng ea lekanngoa. Phahamisa merero ea hau ka ho nepahala, ho ts'epahala, le tiisetso ea liphetho tsa maemo a profeshenale.