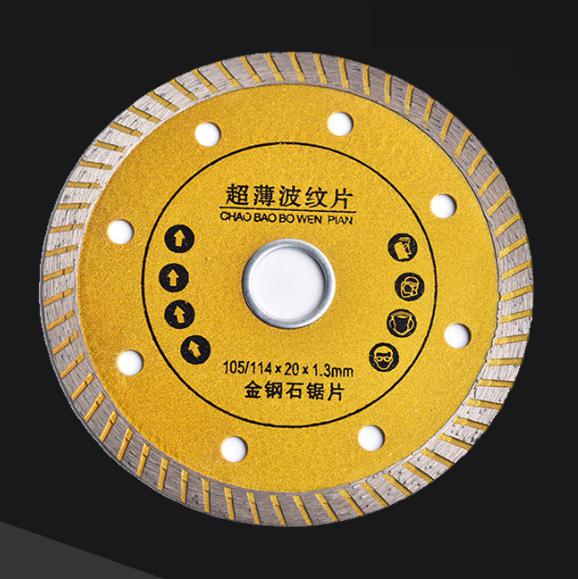

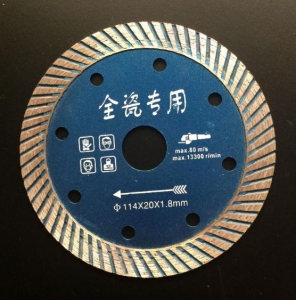

Hantechn@ High Hardness Laser Welded Sintered Diamond Saw Turbo Diamond Cutting Blades

Qala leeto la ho nepahala le ho sebetsa hantle ka Hantechn@ High Hardness Laser Welded Sintered Diamond Saw Turbo Diamond Cutting Blades. E etselitsoe ho nepahala, li-blade tsena tsa turbocharged li bonts'a theknoloji e tsoetseng pele. Mohaho o entsoeng ka laser-welded o tiisa matla a ke keng a lekanngoa le botsitso, ho fana ka likheo tse nepahetseng ka matla a turbo a ekelitsoeng.

Hore na o rakonteraka ea hloahloa kapa moratuoa ea inehetseng oa DIY, li-blade tsena tse sehang taemane tsa turbo li tšepisa ho nepahala, ho etsa hore e 'ngoe le e 'ngoe e be mosebetsi o tsoileng matsoho bakeng sa merero ea hau.

| Li-blades tsa Turbo Diamond Cutting | |||

| Diameter | Sekoti | botegeniki | Maikaelelo |

| 105 limilimithara | 20mm, 22.23mm, 32mm, 50mm | Khatello e batang Tobetsa e Chesang Ho chesoa ka laser | Formarble, granite, ceramic, konkreite |

| 115 limilimithara | 20mm, 22.23mm, 32mm, 50mm | Khatello e batang Tobetsa e Chesang Ho chesoa ka laser | Formarble, granite, ceramic, konkreite |

| 125 limilimithara | 20mm, 22.23mm, 32mm, 50mm | Khatello e batang Tobetsa e Chesang Ho chesoa ka laser | Formarble, granite, ceramic, konkreite |

| 150 limilimithara | 20mm, 22.23mm, 32mm, 50mm | Khatello e batang Tobetsa e Chesang Ho chesoa ka laser | Formarble, granite, ceramic, konkreite |

| 180 limilimithara | 20mm, 22.23mm, 32mm, 50mm | Khatello e batang Tobetsa e Chesang Ho chesoa ka laser | Formarble, granite, ceramic, konkreite |

| 230 limilimithara Oboholo bo sebetsang | 20mm, 22.23mm, 32mm, 50mm | Khatello e batang Tobetsa e Chesang Ho chesoa ka laser | Formarble, granite, ceramic, konkreite |

Fetolela boiphihlelo ba hau ba ho itšeha ka lisebelisoa tsa rona tsa laser-welded sintered diamond seha li-blades tsa turbo diamond seha, tse entsoeng ka boqhetseke bakeng sa ts'ebetso e phahameng le katleho. Ikakhele ka setotsoana likarolong tse ikhethang tse khethollang li-blade tsena:

Bokhoni ba Taemane bo thata bo phahameng

Fumana theknoloji e tsoetseng pele ka li-blade tse entsoeng ka litaemane tse thata haholo. Li-blades tsena li tšepisa ts'ebetso e phahameng ea ho itšeha, ho netefatsa bophelo bo bolelele le ho nepahala ho fihlelang litekanyetso tse phahameng ka ho fetisisa. Phahamisa mesebetsi ea hau ea ho itšeha ka li-blade tse etselitsoeng bokhabane.

Theknoloji ea Laser-Welded

Ho kopanngoa ha matla le botsitso ho matsohong a hau ka theknoloji ea rona ea laser-welded. Kaho e matlafatsa lehare la lehare, e fana ka ts'ebetso e tšepahalang le e se nang moeli nakong ea mosebetsi o mong le o mong oa ho seha. Amohela ho nepahala le ho tšoarella ka har'a sephutheloana se le seng se se nang seamless.

Sintered Diamond Turbo likarolo

Turbocharge lebelo la hau la ho itšeha le katleho ka ho kenyelletsa likarolo tsa sintered diamond turbo. Likarolo tsena tse tsoetseng pele li kenya letsoho ho eketseng katleho ea ho itšeha, ho etsa hore li-blades tsa rona li tšoanelehe bakeng sa mefuta e fapaneng ea ho itšeha. Ntlafatsa ho tenyetseha ha hau ka li-blade tse etselitsoeng mesebetsi e fapaneng.

Tšebeliso e fapaneng

Li-blade tsa rona tsa ho seha taemane ea turbo li etselitsoe ho ikamahanya le maemo, li li etsa tse loketseng mesebetsi e mengata e fapaneng ea ho itšeha. Ho tloha ho lisebelisoa tse fapaneng ho isa ho merero e fapaneng, li-blade tsena li ikamahanya le litlhoko tsa hau, li netefatsa liphetho tse tsitsitseng le tsa botsebi nako le nako.

Turbo Design Ka katleho

Moralo oa turbo ke ho otla ha pelo ho sebetsang hantle, ho eketsa lebelo la ho itšeha bakeng sa ts'ebetso e se nang moeli le e hlahisang litholoana. Tlohela ho itšeha ka botsoa 'me u amohele bokhabane bo tlisoang ke moralo oa turbo mererong ea hau. Eba le phapang pakeng tsa seha se seng le se seng.

Matla a Phahameng a Maemo a Phephetso

Boima bo phahameng ba li-blades tsa rona bo tiisa ho tiea le ho nepahala, esita le maemong a thata ka ho fetisisa a ho itšeha. Sebetsana le merero e hlokang boitlamo ka kholiseho, u tseba hore li-blade tsa rona li etselitsoe ho sebetsa hantle maemong ohle, ho fana ka liphetho tse ikhethang.

Liphetho tsa Kereiti ea Setsebi

Hore na o mokonteraka ea nang le boiphihlelo kapa moratuoa ea inehetseng oa DIY, daemane ea rona e entsoeng ka laser-welded sintered blades ea turbo diamond cut blades e tiisa sephetho sa seho sa boemo ba litsebi. Phahamisa mesebetsi ea hau ea ho itšeha ka nepo, lebelo, le tiisetso ea ts'ebetso e phahameng.

Eba le boemo bo latelang ba ho seha ka bokhabane—moo ho thatafalang ho hoholo, moralo oa turbocharged, le laser-welded mastery li kopanang bakeng sa liphetho tse ke keng tsa bapisoa. Etsa hore karolo e 'ngoe le e 'ngoe e fokotsehe ka li-blades tse hlalosang bokhabane lefatšeng la theknoloji ea ho itšeha.